Laminar Flow Element evaluation – how does it work?

The physical behaviour of Laminar Flow Elements is based on the Hagen–Poiseuille equation. Subsequently the pressure drop of a laminar flowed tube section is directly proportional to the flow rate.

Laminar flow is a requirement for the function of the Laminar Flow Element. This presupposes a Reynolds number of smaller than 2300, which depends on viscosity, tightness and flow rate and also on the geometry of the pipe. To reach laminar flow inside the LFE, the volume flow of large flows must be divided in a number of capillaries.

Test section design and flow evaluation with Laminar Flow Elements:

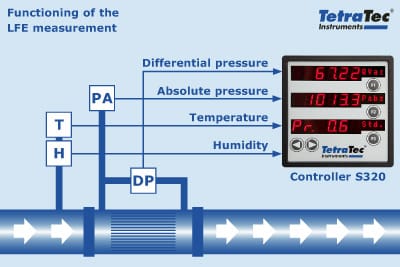

For flow measurement with LFEs a differential pressure, an absolute pressure and a temperature sensor must be provided in the test section design. The measurement of humidity is optional.

The current density and viscosity of the medium is calculated by the sensor data. Together with the characteristics and the differential pressure the current flow results from the calibration characteristic curve of the LFE.

The recording of the sensor data and the calculation of the flow values are carried out the easiest way by our efficient flow computer.

The very linear relation between flow and differential pressure distinguishes laminar flow elements from all other differential pressure procedures in a unique way, as orifice measurement, for example. Therefore a Laminar Flow Element can cover wide ranges of 1:10 up to 1:100, which may otherwise require at least two to four different venturis, nozzles or orifices at the same differential pressure measuring range.

The accuracy at the lower end of the range will be limited only by the flow stability and by the evaluation of the differential pressure signal.

Therefore Laminar Flow Elements have decisive advantages in practice!

Laminar Flow Elements

Flow calculation according to Hagen–Poiseuille or Uniflow

More information and technical details can be

found in the data sheet and on the product page